PILE FOUNDATION:

Pile foundations are the most commonly used deep foundation. They consist of spread/grillage footing, supported on piles that go deep down up to the depth where a good bearing stratum is available. Pile foundations are used in the following situations:

2. When the soil is waterlogged.

3. When the structural load is heavy and uneven.

4. When there is a danger of scouring action of water, as in the case of structures to be constructed on the river bed or near the seashore.

CLASSIFICATION OF PILES:

Piles are classified based on the following criteria:

(1) Based on the function.

(2) Based on the material of construction.

Classification Based on the Function Depending upon the function or the use, piles may be classified as follows:

1. Bearing Piles:

Bearing piles are those piles that transfer the load, through weak/soft soil or water, to a suitable hard stratum. These piles are driven into the ground until a suitable hard stratum, having the required bearing capacity, is reached. These piles do not take any load themselves, but only transfer the load to the stratum, by bearing at the end.

|

| Fig 2.11 Bearing Piles |

2. Friction Piles:

Friction piles transfer the load by the friction (skin friction) developing along the surface of the pile and the surrounding soil. These piles are used in weak or soft soils when a suitable hard stratum is not available at an appropriate depth. These piles are also called floating piles.

3. Friction Cum Bearing Piles:

These piles transfer the load by bearing as well as friction. These piles rest on a hard stratum. These piles are used when the bearing capacity of the available hard stratum is less than the load coming on the piles.

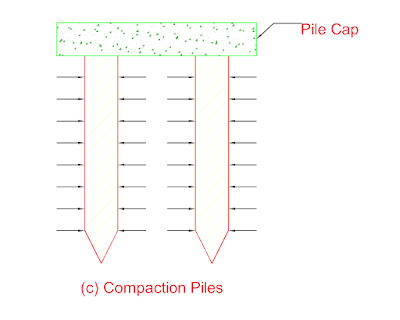

4. Compaction Piles:

Compaction piles are used to compact the loose granular soils. These piles result in an increase in the bearing capacity of the soil. They may be made up of weaker material as the pile does not carry any load itself but only compacts the soil.

5. Sheet Piles:

Sheet piles are used to retain soil. They act as retaining walls to support the soil laterally which may come out under pressure. Sheet piles are also used to prevent leakage/seepage by providing an impervious layer. These piles do not take or transfer any load. These are also used to prevent erosion of river banks or to retain the sides of foundation trenches.

6. Anchor Piles:

Anchor piles provide support against the horizontal force from sheet piling, piles, or other earthwork embankments.

7. Batter Piles:

These piles are driven at an inclination to resist large horizontal or inclined forces.

8. Fender Piles:

These piles are used to protect waterfront structures from the impact of ships. These piles are generally made up of timber.

Classification of Piles Based Upon Material of Construction Based upon materials of construction, the piles are divided into the following types:

(1) Steel Piles

(2) Cement concrete piles

(3) Timber piles

(4) Sand piles

(5) Composite piles

Steel Piles:

Steel piles are used for transferring heavy loads through soft soils to deep strata. These piles require heavy equipment and machines for driving. These piles should be surface treated or encased to prevent corrosion. Steel piles are available in various shapes such as pipes, boxes, rolled steel sections, etc.

(i) Steel Pipe Piles:

Their pipes are driven into the soil to the required depth and cleared from the soil inside. After that, the pipes are filled with cement concrete. These pipes are used for transferring heavy loads to deeper depths, through soft soil, where proper bearing stratum is available.

(ii) Rolled Steel H-beam Piles:

This type of pile consists of a rolled steel H-section which can be driven easily into the soil. They are useful for deep penetration and can be lengthened as per the requirement. These piles can be used for retaining walls, bulkheads, bridges, etc.

Cement Concrete Piles:

Cement concrete has high compressive strength which makes it suitable as a pile. These piles are strong and durable and can be cast in any size.

Concrete Piles may be further classified into the following types:

(1) Precast Piles

(2) Cast in Situ Piles

(3) Prestressed Concrete Piles

(1) Precast Piles:

These types of piles are manufactured in the factory and brought to the site and driven into the ground. These are made up of reinforced cement concrete and are available in many shapes. such as square, rectangular, circular and octagonal, etc. Precast piles are available in lengths up to 30 m and diameter ranging from 400 mm to 650 mm. The reinforcement bars are placed longitudinally in the concrete and are tied with lateral reinforcement, 5 mm to 10 mm in diameter. The main bars (vertical reinforcement) are of 20 mm to 40 mm diameter and are placed at least one at each corner of the piles. The bars are protected with a concrete cover of 50 mm. These piles are provided with a steel shoe at the end which not only protects it but also helps in driving the pile into the ground.

(2) Cast in Situ Piles:

Cast in situ pile is constructed at the site in its location. They are of two types:

(a) Driven piles

(b) Bored piles

(a) Cast in situ driven piles:

This type of pile is constructed by driving a steel tube or casing into the ground having an internal diameter equal to the diameter of the pile. The tube is driven with the help of pile driving equipment. The concrete is poured into the tube, after putting the required reinforcement cage into the tube. The tube/casing provided may be removed or left in its place. If the casing is removed it is called an uncased pile, but if it is allowed to remain in its place it is called a cased pile. Figure 2.12 shows the construction of a driven cast in situ pile.

|

| Fig. 2.12 |

Other types of cast in situ (driven) piles are available in the market under various trade names, some of which are listed below:

(1) Simplex pile

(2) Raymond pile

(3) Mc-Arthur piles

(4) Franki pile

(5) Vibro pile

(b) Bored Piles:

Bored piles are constructed by forming a borehole in the ground and then filling it with concrete. These piles may be cased or uncased. No heavy pile driving instrument is required for these piles. Bored piles are used when the hard-bearing strata is too deep to be reached by driven piles. Bored piles also have an advantage over driven piles in that they are not subjected to any kind of vibrations.

Bored piles are of three types:

(1) Pressure piles

(2) Under reamed piles

(3) Compaction Piles

(i) Pressure Piles:

Pressure piles are constructed by sinking a steel tube with the help of auger boring and compressed air. These piles are used in places where it is not possible to use pile driving equipment.

(ii) Underreamed Piles:

Under reamed piles are bored concrete piles which have one or more enlarged portions, near the base, called bulbs. The bearing capacity of such piles is increased by increasing the number of bulbs. They are constructed with the help of under-reaming tools.

These piles are the safest and economical foundation in black cotton soil or expansive soils. When this pile has one bulb it is called a single under the reamed pile and if it has more than one bulb, then it is called a multi under the reamed pile. Figure 2.13 shows a single under-reamed pile.

|

| Fig. 2.13. |

(iii) Compaction Piles:

These piles are just like under-reamed piles but with a difference that the reinforcement cage is not put in the borehole before concreting. After the concreting, the reinforcement cage is driven into the fresh concrete, causing compaction of the concrete. Their load carrying capacity is more than under-reamed piles. These piles are used in the case of loose sandy soils.

Prestressed Concrete Piles:

Prestressed concrete piles are precast into the factories and are lighter in weight as compared to precast concrete piles. These piles are manufactured just like the RCC piles but with the difference that the reinforcement cables are prestressed. These piles are lighter in weight and durable as compared to RCC piles. They have higher load carrying capacity also. Due to these reasons, prestressed concrete piles have become very popular nowadays.

2.8.2.3. Timber Pile:

Timber pile is made from the stem of a hardwood tree like sal, teak, semul, deodar, chir, and babul, etc. These piles are provided with a cast-iron shoe at the bottom. The commonly available size of the pile is 30 to 50 cm in diameter. In order to protect the head of the pile during pile driven an iron ring is fixed at the top.

These piles are cheap and can be easily driven into the ground. Timber piles, treated with creosote oil are commonly used for marine works or when subsoil water is present. These piles transfer the load by developing skin friction between the pile and the ground soil. These piles are light and economical and used for small loads.

2.8.2.4. Sand Piles:

Sand piles are made by filling sand in boreholes. The top of the sandpile is covered with concrete. These piles are suitable for taking lighter loads only. These are generally used in road embankments. Figure 2.14 shows a sand pile.

|

| Fig. 2.14 |

2.8.2.5. Composite Piles:

Composite piles are made up of more than one material. For example timber and concrete or concrete and structural steel sections. Figure 2.15 shows a timber and concrete composite pile having a lower timber portion and an upper portion of concrete.

|

| Fig 2.15 |

0 comments:

Post a Comment